Caulk nozzle design by Sopi embodies our commitment to precision and performance. In the world of professional sealant application, control and accuracy are everything. That’s why we design each caulk nozzle to help users achieve clean, consistent results, no matter if they’re sealing industrial joints or applying adhesives in complex assemblies.

We understand that a well-designed sealant nozzle can be the difference between a professional finish and one that needs rework. From its internal geometry to its flow dynamics, every feature is tested and refined to ensure optimal dispensing performance across a wide range of materials.

What Makes a Nozzle Truly Efficient

For us, efficiency starts with engineering. Each caulk nozzle is built to deliver a steady, even flow with minimal back pressure. This means the user exerts less effort while maintaining better control over bead shape and size. Our research and development team continuously explores ways to reduce material waste, ensuring that every drop of sealant, silicone, or adhesive reaches its intended surface with maximum precision.

We use high-grade, chemical-resistant materials to guarantee durability under demanding work conditions. No matter if you’re working with thick construction-grade sealants or delicate finishing adhesives, our silicone sealant nozzles are made to perform consistently without deformation or blockage.

The design process doesn’t stop at manufacturing. We also collaborate with end users to test each nozzle in real applications. This direct feedback loop helps us improve small but critical details, such as threading fit, angle accuracy, and compatibility with various cartridge and gun systems.

The Role of Caulking Nozzle Tips in Professional Work

To enhance flexibility in the field, we developed specialised caulking nozzle tips that attach easily to our standard nozzles. These tips allow professionals to adapt their dispensing patterns quickly, without replacing the entire system. For instance, when moving from a wide joint to a narrow groove, switching caulking tips can provide immediate control over bead width and material flow.

Each of our caulking nozzle tips is designed with precision-moulded outlets to maintain consistent bead geometry. This consistency is especially important when applying sealants in architectural detailing, glazing, or waterproofing, where visible results matter just as much as structural performance.

We also focus on durability, using materials that resist clogging, pressure deformation, and chemical erosion. By extending the working life of these accessories, caulking nozzle tips reduce downtime, replacement costs, and overall waste.

Reliable Compatibility with Any Caulking Gun Nozzle

Compatibility is key in professional environments where efficiency drives productivity. That’s why our system integrates seamlessly with any caulking gun nozzle configuration. Whether a user operates pneumatic, manual, or battery-powered dispensing tools, the transition between components remains smooth and secure.

Every caulking gun nozzle we test undergoes strict quality control to ensure uniform dispensing pressure and reduced turbulence within the flow channel. These design refinements make a significant difference in maintaining even distribution across long application lines.

The adaptability of our caulking gun nozzle solutions also helps minimise rework. By delivering a consistent bead, users spend less time correcting uneven surfaces or excess material buildup, two of the most common causes of inefficiency in professional sealing operations.

Why Precision in Caulk Tools Design Matters

The importance of a high-quality caulk nozzle goes beyond simple dispensing. It directly affects material use, aesthetic quality, and even structural integrity. Uneven application can lead to weak joints or visible imperfections, issues that can compromise both function and appearance.

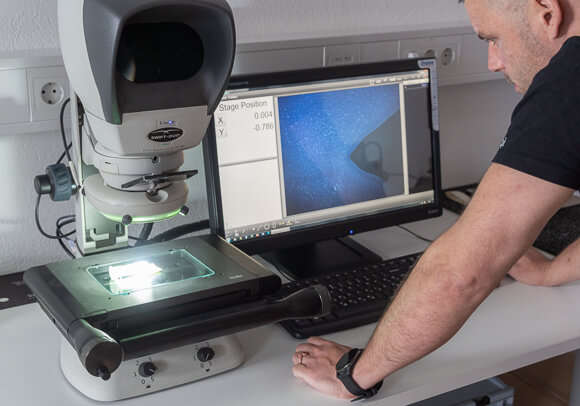

That’s why we invest heavily in precision manufacturing. Using state-of-the-art injection moulding and finishing techniques, each nozzle is built to meet exact specifications for uniform thickness, outlet geometry, and flow resistance. This level of precision helps professionals maintain total control, no matter the sealant type or project scale.

When paired with our Flip’n’Spread system, users can further streamline adhesive spreading, maintaining clean and uniform layers throughout the process. This combination enhances overall efficiency, especially for high-volume or repetitive industrial tasks.

Innovation and Material Science Behind Our Nozzle Range

Continuous innovation keeps us ahead in the dispensing industry. Our engineering team combines polymer science with practical design testing to improve the performance of every caulk nozzle we release. We focus on reducing operator fatigue by designing lighter yet stronger materials, improving flexibility without compromising structural integrity.

Our Commitment to Professional Quality

For our team at Sopi quality is never negotiable. Every caulk nozzle, every attachment, and every caulking nozzle tips system goes through a strict inspection process before shipment. This ensures that professionals receive reliable tools that perform flawlessly from the first use.

Our manufacturing philosophy combines precision engineering with user-focused innovation. We aim to provide tools that enhance productivity, reduce waste, and uphold the highest standards of craftsmanship. The same dedication applies to our caulking gun nozzle products, designed to complement various adhesives and sealant systems across industries.

As industries evolve and application needs grow more complex, our mission remains simple: to deliver smarter, more efficient dispensing solutions that help professionals achieve cleaner, faster, and more consistent results every day.