-

Izdelki

Plastične konice za nanašanje lepil, pen, silikona in drugih materialovPlas..Plastični adapterji za konice omogočajo enostaven dostop do težko dosegljiv..Podaljšek za kartuše je nepogrešljivo orodje, zasnovano za enostaven dostop..Konice za klobase so vsestranski in nepogrešljivi pripomočki, ki se pogosto..Pokrov za kartuše ponuja priročno rešitev za ohranjanje silikonov in drugih..Naše plastične konice za avtomobilsko in ladijsko industrijo so zasnovane t..Ploščate konice, znane tudi kot trakaste konice, so nepogrešljiva orodja za..Nadomestne konice so zanesljive in odporne ter omogočajo popoln nadzor nad ..Konice za lastne blagovne znamke so izdelane po meri in po stroškovno ugodn..Laboratorij za razvoj konic nam omogoča razvoj visokokakovostnih izdelkov p..Flip’n’Spread prinaša revolucijo na področju natančnega nanašanja različnih..Perforirani plastični tulci zagotavljajo trdne spoje, saj omogočajo natančn..Mešalne konice omogočajo hitro in čisto mešanje dvokomponentnih lepil, ki s..

- Rešitve za nanašanje

- Flip'n'Spread

- Nozzle Lab

- Zakaj izbrati Sopi

- O nas

- Kontakt

Rešitve za nanašanje po meri

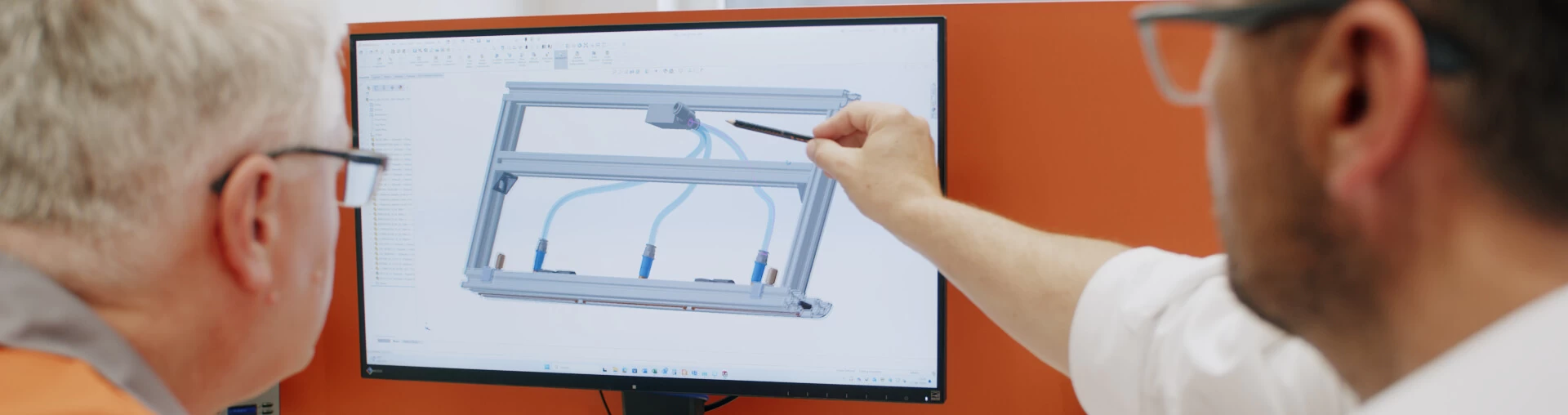

Nozzle Design Lab je opremljen z vsemi orodji, potrebnimi za pretvorbo ideje v končni dizajn in njegovo izdelavo v želenih količinah. To nam omogoča, da nudimo prilagojene in stroškovno učinkovite rešitve za specifične stranke in industrije.

Strokovna izdelava

Specializirani smo za reševanje edinstvenih izzivov, tudi tistih najzahtevnejših.

S popolnim razumevanjem vaših zahtev oblikujemo izdelke, ki ustrezajo vašim potrebam.

Naš pristop temelji na sodelovanju, doseganju ciljev in zagotavljanju vrhunskih rezultatov.

S popolnim razumevanjem vaših zahtev oblikujemo izdelke, ki ustrezajo vašim potrebam.

Naš pristop temelji na sodelovanju, doseganju ciljev in zagotavljanju vrhunskih rezultatov.

Študije primerov

Študija primera: Prilagojen adapter za 29 oz ameriške kartuše

Razvito v SOPI Nozzle Design Labu

V industriji nanašanja lepil je združljivost med kartušami in orodji za nanašanje ključnega pomena za učinkovitost in natančnost. SOPI je prejel izziv: ustvariti prilagojen adapter, ki bi omogočal, da se 29 oz. ameriške kartuše brez težav uporabljajo z našim sistemom Flip’n’Spread.

Ta projekt je postal priložnost, da predstavimo zmogljivosti našega Nozzle Design Laba, kjer kompleksne zahteve industrije pretvorimo v funkcionalne rešitve.

Se soočate z edinstvenim izzivom ali zahtevnim projektom?

Vedno smo pripravljeni pomagati pri razvoju visokokakovostnih, po meri izdelanih rešitev na področju nanašanja. Ne odlašajte – naredite naslednji korak in nas kontaktirajte.

Imate kakšno vprašanje? Pošljite nam elektronsko sporočilo.

HITRA ODZIVNOST

Naša ekipa za raziskave in razvoj učinkovito rešuje težave ter je pripravljena na vaše izzive. Z lastnim razvojem bistveno skrajšamo proces od ideje do proizvodnje.

MAJHNE KOLIČINE

Potrebujete samo prototip? Ni problema. Izdelujemo od nekaj sto do več deset tisoč konic, saj verjamemo, da je nenehna inovacija ključ do prelomnih rešitev v serijski ali nizko-volumski proizvodnji.

DOSTOPNE CENE

Napredna oprema in lasten oddelek za raziskave in razvoj nam omogočata proizvodnjo visokokakovostnih, po meri izdelanih izdelkov po konkurenčnih cenah. Te rešitve so prilagojene specifičnim strankam ali industrijam.

Iščete nanašalnik po meri?

Pomagali vam bomo pri izdelavi nanašalnikov po meri.

Naredite naslednji korak in stopite v stik z nami.

Prosimo, pustite svoje kontaktne podatke in kratek opis vašega projekta.

Odgovorili vam bomo v najkrajšem možnem času.

Naredite naslednji korak in stopite v stik z nami.

Prosimo, pustite svoje kontaktne podatke in kratek opis vašega projekta.

Odgovorili vam bomo v najkrajšem možnem času.